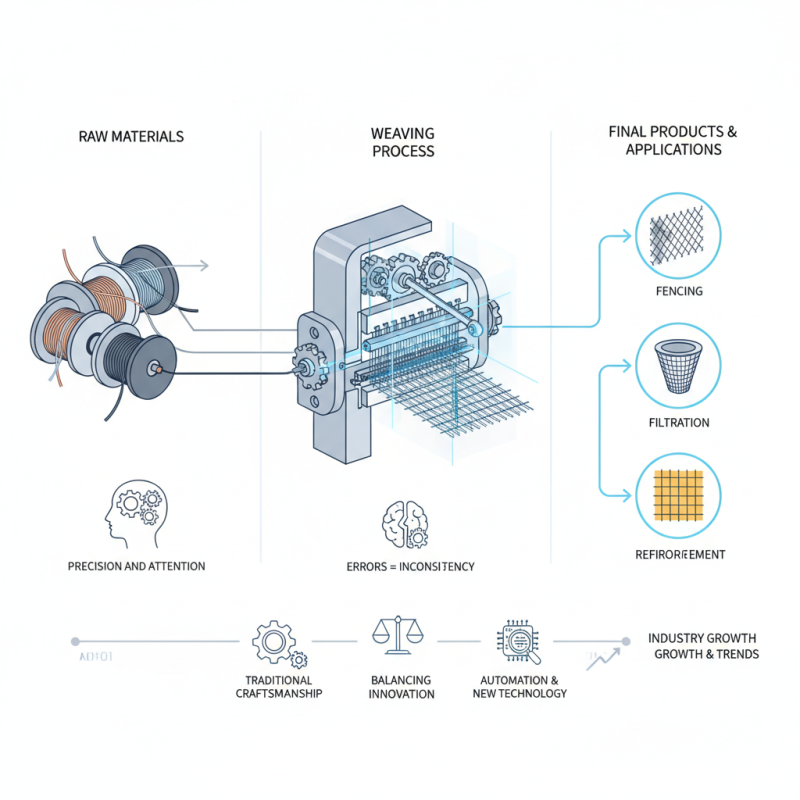

A wire mesh weaving machine is a key player in various industries, from construction to agriculture. As expert John Smith, a veteran in the field, states, "The wire mesh weaving machine transforms raw materials into essential products." This machine weaves wires into a durable mesh, offering versatility in applications.

The process begins when wires are fed into the machine. Each wire is meticulously interlaced to form a robust grid. The weaving process requires precision and attention. Subtle errors can lead to inconsistency in the final product. The output is often used for fencing, filtration, and even reinforcement.

In an era where automation prevails, the wire mesh weaving machine is still evolving. New technology brings efficiency but also challenges. Balancing innovation with traditional craftsmanship is crucial. As the industry grows, staying updated with trends is vital. The woven mesh must meet various standards, ensuring it serves its intended purpose effectively.

A wire mesh weaving machine is a specialized device used to create wire mesh. It interlaces wires to form an open, grid-like structure. Commonly, these machines operate with either vertical or horizontal weaving methods. The intricacies of their design allow for multiple patterns and thicknesses.

The process begins with feeding metal wires into the machine. The wires can vary in material and diameter. As the machine weaves, the wires are positioned with precise tension. This is crucial for durability. Mesh can be made tighter or looser, based on intended use. Operators must monitor quality throughout the process, ensuring no defects.

These machines can be quite complex. Yet, understanding their mechanics can be challenging. Maintenance is also vital, as wear and tear happen. Regular checks on moving parts can prevent downtime. It's important to reflect on efficiency and output.

Improvements in weaving machines contribute to better production rates. Modern techniques are evolving but still have limitations. The quest for perfection continues.

A wire mesh weaving machine is crucial for creating various types of wire mesh, widely used in construction and other industries. Understanding its key components is essential for optimizing its functionality. The machine features a weaving mechanism, which intertwines wires to create mesh patterns. This mechanism can vary depending on the desired mesh type.

Another significant component is the feeding system. It holds the wire spools, ensuring a steady supply of wire during weaving. If the feeding system jams, it can disrupt production. Regular maintenance is vital to prevent such issues. The tension control system is equally important. It regulates wire tension, which affects the final mesh quality. Too much tension can lead to material breakage.

Tips: Regularly check the machine’s components for wear and tear. A small issue can escalate. Consider taking notes during maintenance tasks to track changes over time.

Evaluate the quality of the woven mesh often. If the patterns are inconsistent, revisit the tension settings and weaving process. Remember, small adjustments can lead to significant improvements.

A wire mesh weaving machine operates through a detailed process. The weaving begins with feeding wire into the machine. This wire is typically metal, offering strength and durability. The machine then straightens and cuts the wire to specific lengths. This initial preparation is crucial for quality output.

Once prepared, the wire goes through the weaving phase. The machine uses a shuttle to create perpendicular patterns. It alternates the horizontal and vertical wires seamlessly. Watching this process in action reveals the intricate dance of metal against metal. It’s fascinating yet can feel mechanical. The machine misaligns sometimes, requiring immediate attention to maintain the mesh quality.

After the weaving, the mesh is checked for consistency. Inspection includes measuring the dimensions and identifying any defects. Even minor flaws can affect the final product's integrity. The final step often involves re-weaving or cutting imperfections. The entire process illustrates craftsmanship, but it's not without its challenges. Each stage demands precision and care.

Wire mesh products are versatile materials with numerous applications across various industries. They are made from different metals and can vary in thickness and weave patterns. This adaptability makes them essential for construction, agriculture, and food processing. In construction, wire mesh is used as reinforcement in concrete. It helps to maintain structural integrity, ensuring buildings withstand the test of time.

In agriculture, wire mesh serves multiple purposes. It keeps pests away from crops, allowing farmers to protect their yield. Fencing made from wire mesh is essential for livestock management. However, it needs regular maintenance to prevent rust and wear. The food industry also benefits greatly. Wire mesh is crucial in filter and drainage systems. It ensures cleanliness and safety in food production.

Despite its many uses, there are limitations to wire mesh products. For instance, improper installation can lead to failures. Additionally, the choice of material is critical. Using the wrong type can result in inefficiency and increased costs. The shortcomings in manufacturing quality can also affect the longevity of wire mesh solutions. Investing in high-quality materials is vital but often overlooked. Ultimately, understanding both the advantages and potential pitfalls of wire mesh can be the key to maximizing its benefits.

Wire mesh weaving machines are critical in various industries. Proper maintenance ensures optimal performance and longevity. Regular inspections are essential. Visual checks help identify issues early. For instance, a worn-out part can affect production speed. According to industry reports, machines with a 90% uptime reduce operational costs significantly.

Tips for maintenance include lubricating moving parts regularly. This reduces friction and wear. Keeping the machine clean also prevents debris buildup. Dust and debris can affect the quality of the woven mesh. Additionally, check the tension of the wires. Inconsistent tension can lead to defects.

Operators should undergo training. Proper training minimizes mistakes. Understanding the machine's functions can enhance efficiency. However, it’s easy to overlook small issues. A tiny misalignment can cause significant downtime. Cultivating a routine can make a considerable difference. Regular care allows for smooth operations and high-quality output.

This bar chart represents the efficiency of wire mesh weaving machines over the first seven months of the year. As seen, the efficiency shows a steady increase, reaching a peak in July with 92%. Regular maintenance and proper care are essential to achieve optimal performance and enhance longevity.