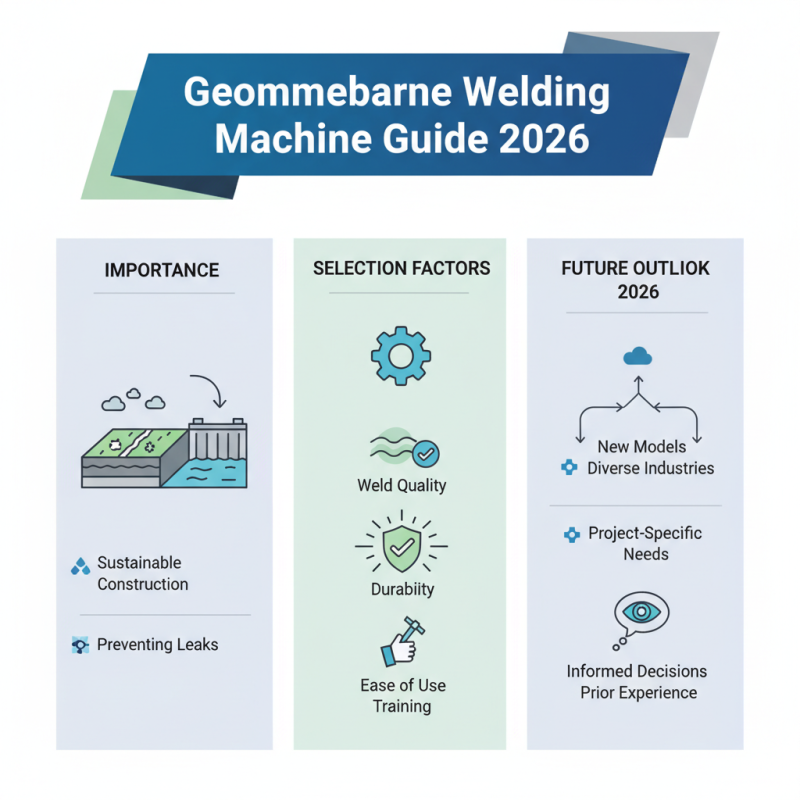

As the demand for sustainable construction grows, the importance of the geomembrane welding machine increases. These machines are essential in various applications, such as landfill and water reservoir projects. In 2026, choosing the right geomembrane welding machine will be critical for efficiency and reliability. Many models offer advanced features, but not all meet every need.

Several factors play a role in selecting the best machine. The quality of welds is crucial. A poorly welded seam may lead to leaks, causing significant problems. Durability and ease of use are other important aspects. Some machines can be complex. Operators need training to ensure they function effectively.

What's on the market? Manufacturers will release several models aimed at diverse industries. However, not every option suits every project. Often, reflecting on prior experiences can inform better decisions. This landscape will evolve, but careful consideration remains vital for success in using a geomembrane welding machine.

Geomembrane welding machines are essential in the construction and environmental industry. These machines create seams that are crucial for the integrity of various projects. Their effectiveness depends on several factors, such as type, temperature, and pressure settings.

Choosing the best machine can often be challenging. Consider the thickness of geomembranes you will be working with. A machine’s specifications should match the materials. Operators need to be skilled; improper use can lead to weak seams. The adjustment of temperature and speed is vital for strong welds.

**Tips:** Always test weld in a controlled setting. This helps in understanding how the machine performs with specific geomembranes. Keep the workspace clean to avoid contamination. It’s also wise to maintain your equipment regularly. Neglect can lead to sudden failures.

This field has advancements, but some machines still show flaws. New models promise efficiency, yet they sometimes fall short in real-world applications. Users may face issues with inconsistent welding quality, even in high-end machines. Therefore, it's wise to research user reviews before making a purchase. Be prepared to adapt and refine your techniques.

When selecting a geomembrane welding machine, several key features must be considered. The machine's welding speed is crucial, especially in projects requiring rapid completion. Reports show that high-efficiency machines can achieve welding speeds up to 12 meters per minute. This could significantly reduce project timelines.

Another essential feature is the temperature control system. Precise temperature settings can ensure optimal weld quality. Machines with advanced temperature control can minimize the risk of damage to the geomembrane material. Data indicates that improper temperature settings can lead to weld failures in up to 30% of projects.

Durability and ease of maintenance should not be overlooked. Machines constructed with robust materials can withstand harsh job site conditions. They often require less frequent repairs, saving time and costs in the long run. However, some users report that even high-quality machines can experience unforeseen breakdowns, leading to disruptions. Regular maintenance schedules can mitigate these issues.

By focusing on these features, one can enhance the overall efficiency and reliability of geomembrane installation projects.

| Feature | Description | Importance |

|---|---|---|

| Welding Speed | The rate at which the welding machine can complete joins. | High welding speed improves project efficiency. |

| Temperature Control | Ability to precisely set and maintain welding temperatures. | Critical for ensuring quality welds and preventing material damage. |

| Weight | The overall weight of the machine affecting its portability. | Lighter machines are easier to transport and maneuver. |

| Durability | Resistance to wear and tear in various working conditions. | Longer lifespan reduces replacement costs. |

| User Interface | Ease of use and clarity of controls. | Simpler operation boosts productivity and safety. |

| Power Options | Available power sources, including electric and gas. | Flexibility based on site needs can lead to increased convenience. |

| Warranty | Coverage offered for parts and service after purchase. | Extended warranty indicates manufacturer confidence in product quality. |

In 2026, geomembrane welding machines are crucial for various projects. The best machines come with advanced features, offering efficiency and durability. Users value machines that provide consistent welds and are easy to operate. Various brands provide unique offerings, catering to different needs.

Tips: Always check for user reviews. They often highlight strengths and weaknesses of machines. A machine’s performance can vary based on the welding environment. Temperature, humidity, and material type affect outcomes.

Investing in quality machines pays off. Look for features like automatic controls and adjustable speeds. Some users have reported issues with certain models overheating. This can lead to incomplete welds and project delays. Be cautious about machine specifications and maintenance requirements.

Tips: Regular maintenance can prevent many problems. Ensure routine checks and cleaning are part of the process. This can enhance the machine's lifespan significantly.

Innovative technologies are reshaping the landscape of geomembrane welding machines in 2026. These advancements focus on efficiency, precision, and user-friendliness. Modern machines now feature smart temperature controls, leading to higher quality welds. Enhanced user interfaces enable better control, reducing the learning curve for new operators.

Tips: Always test your equipment before starting a project. This helps identify any issues early. Inspect the welding settings carefully to avoid costly errors.

New welding machines incorporate automation, minimizing manual labor. However, automation can also lead to overreliance on technology. Operators should remain vigilant and aware of potential malfunctions. Regular training can keep skills sharp and maintain a balance between automation and manual oversight.

Tips: Schedule regular equipment maintenance. A well-maintained machine performs better and lasts longer. Document any inconsistent performances to improve future projects.

When looking for the best geomembrane welding machine in 2026, user reviews offer valuable insights. Many operators appreciate machines that are easy to use. These machines should allow for quick adjustments and seamless operation. Some users recommend considering tools with intuitive controls. A clear interface can significantly reduce the learning curve for new operators.

Durability is also a key factor in user satisfaction. Operators frequently mention that machines must withstand harsh conditions. A robust build contributes to long-term reliability. However, some users have faced issues with overheating during extended use. They suggest monitoring temperatures to avoid breakdowns. This is an area needing attention for future designs.

Lastly, the portability of welding machines is a hot topic among users. Machines that are lightweight and compact are preferred. Yet, some users report that smaller machines might lack power. Balancing size and performance remains a challenge. It’s crucial to reflect on these trade-offs when choosing gear. Each operator has unique needs to consider.